Your cart is currently empty!

Ion Exchange Process: Applications, Benefits, and How It Works

Many water purification methods exist but for highly selective ion removal for industrial applications, ion exchange processes come up at the top. It’s a chemical process for improving water quality. The working is simple in theory. It simply swaps undesirable ions in the water with less harmful ions. This chemical process relies on specialized ion exchange resins.

Beyond water softening, ion exchange plays a pivotal role in demineralization, dealkalization, and even specialized tasks like denitrification and disinfection. Ion exchange processes are known for their broad applicability. However, understanding when to implement this technology is crucial.

What Is Ion Exchange Resin and How Does It Work?

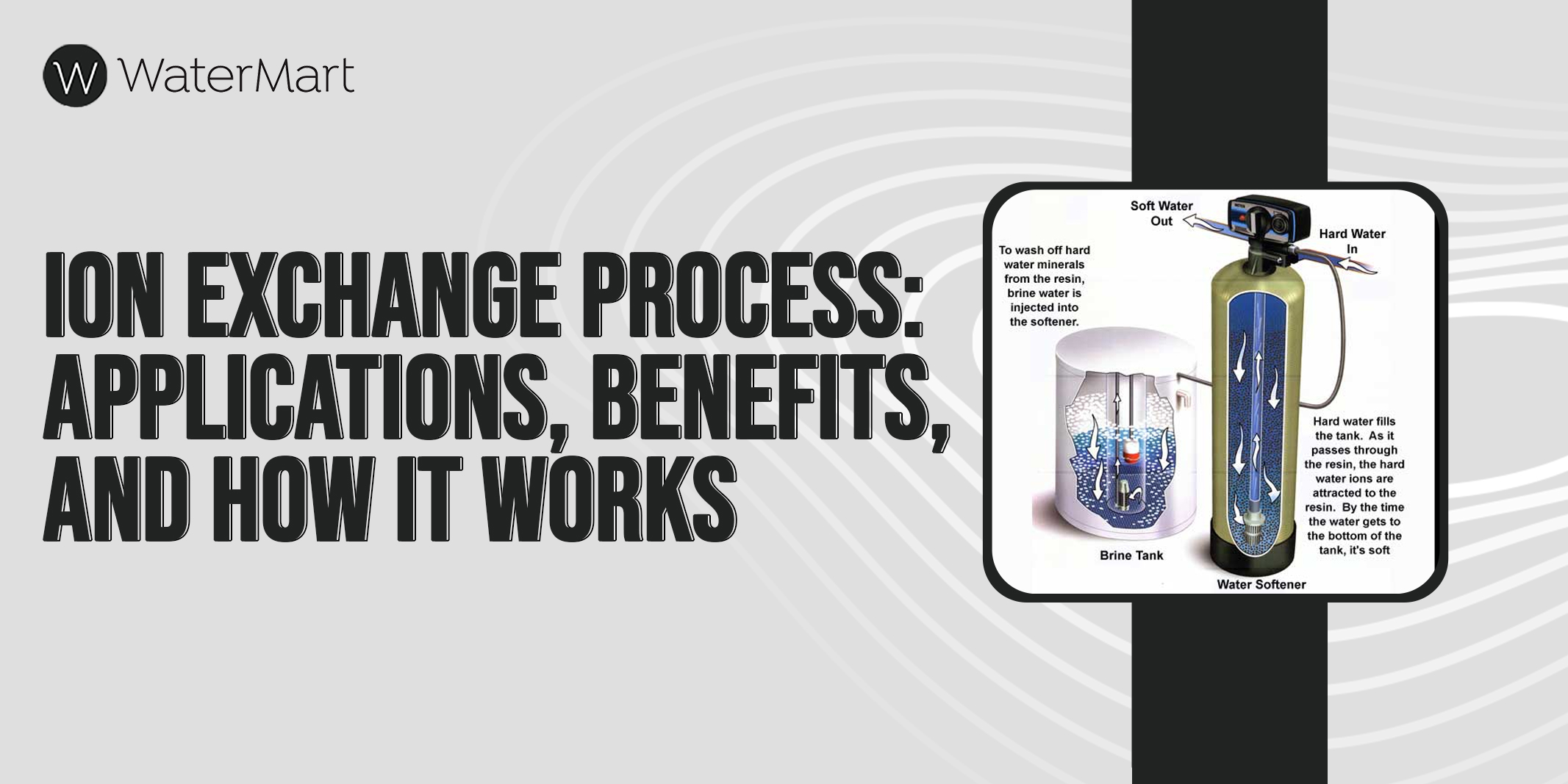

Ion exchange is a water purification method that takes a chemical approach to filter and “soften” water. As told above, it swaps unwanted ions in water with more desirable ions. As a result, it reduces water hardness and removes contaminants. This Ion exchange process happens in various steps, here’s a simple breakdown:

- Hard water (water containing high levels of calcium and magnesium) is made to enter the resin tanks of Ion exchange systems.

- The water passes through resin beds that act like sponges for ions. The resins are specifically designed to attract ions of the opposite charge. For instance, cation resins (-SO₃⁻) are used to trap positively charged ions, while anion resins (-NR₃⁺) capture negatively charged ions. (More on this in the types of resins section!)

- As water flows through these, calcium and magnesium ions are swapped with sodium or potassium ions. This is due to the stronger affinity of the resin for hardness ions like Ca²⁺ and Mg²⁺.

- The water exiting the system now contains less calcium and magnesium. Depending on the system, additional processes may combine the remaining ions to form pure water (H₂O).

- The treated water is softened and suitable for various uses, such as cleaning or industrial processes.

- Over time, the resin becomes saturated with hardness ions and loses its ability to facilitate ion exchange. To restore its effectiveness, the resin is regenerated using a concentrated brine solution. (See this in detail below!)

Principles at Play: The effectiveness of ion exchange depends on the principles of ion attraction and repulsion.

Types of Ion Exchange Resins

There are different types of ion exchange resins. They all are made from polyacrylate or polystyrene but have differently charged ions for removing specific ions from water. Here are the main types of ion exchange resins:

- Cation Exchange Resins: These are designed to remove positively charged ions, like calcium and magnesium. They come in two types, Strong Acid Cation Resins (SAC) and Weak Acid Cation Resins (WAC). We use them for water softening, demineralization, and dealkalization.

- Anion Exchange Resins: Just like cation resins, anion resins are categorized into two types. They are Strong Base Anion Resins (SBA) and Weak Base Anion Resins (WBA). Anion resins remove negatively charged ions, like chlorides and nitrates. So, we use these types of resins for removing nitrates, chlorides, and sulfates.

- Mixed Bed Resins: Mixed bed resins combine both cation and anion exchange resins in a single bed. They offer a comprehensive solution for high-purity water needs. These systems are used as a final polishing step in water treatment to achieve ultra-pure water.

Components of the Ion Exchange System

An ion exchange system is made up of several key components that work together to purify water. These parts include ion exchange resins, an inlet distribution system, a regenerant distribution system, retention elements, plc, control valves, and piping. Out of all these, only two key equipment require maintenance in ion exchange systems:

1. Resin Beds

Resin beds hold the ion exchange resins. These beds are packed with tiny resin beads that help remove ions from water as it passes through. The bed ensures that the water and resins have enough contact for effective treatment. See above for working and types of resins.

2. Regeneration Systems

Regeneration systems restore the capacity of the resin after it becomes saturated. They use a chemical solution, like salt, to clean the resin and release the captured ions. This process includes backwashing, regeneration, and rinsing to ensure the resin is ready for use again.

The Regeneration Process

Any water treatment system that uses ion exchange resins needs regular maintenance due to the regeneration process. But why? Over time, the resin bed becomes saturated with contaminants. So, it loses its ability to effectively remove ions. This is when regeneration comes into play.

Regeneration involves flushing the exhausted resin with a special regenerate solution, such as salt, acid, or alkali, to reverse the ion exchange process. This restores the resin’s capacity to continue its function. It’s better to get professionals to do it for you as if not done properly it can make the whole ion exchange process ineffective.

If you ignore regeneration, the resin will eventually stop working. This will lead to contaminant leakage into the treated water. By restoring the resin’s ion-exchanging ability, regeneration ensures the system works efficiently over time.

Ion Exchange in Water Treatment Systems

The above examples are of water softening systems but Ion exchange is used in many other types of water treatment. Below, we break down how ion exchange works in key processes like softening, deionization, dealkalization, and specific ion removal.

Water Softening

Water softening removes hardness-causing ions like calcium and magnesium. These ions are replaced with sodium using a strong acid cation (SAC) resin. The process is called sodium zeolite softening. It is widely used because zeolites excel at ion exchange. This softened water is suitable for medium-pressure boiler feedwater, reverse osmosis systems, and certain chemical processes.

Deionization and Demineralization

- Deionization removes nearly all dissolved ions, producing ultra-pure water. It works by exchanging dissolved salts for hydrogen or hydroxide ions. Depending on the application, industries use mixed-bed or separate-bed deionizers. Both of these use ion exchange resins to offer a cost-effective solution for less stringent applications.

- Demineralization takes ion exchange further. It eliminates all inorganic salts. In this, SAC resin in hydrogen form replaces salts with acids. Then, SBA resin in hydroxide form neutralizes the acids. This process is ideal for industries needing pure water for high-pressure boilers and electronics manufacturing.

Dealkalization

Dealkalization reduces alkalinity by targeting bicarbonates and carbonates. This process is essential for boiler feedwater treatment. In a dealkalizer, carbonate ions are swapped for chloride ions. This lowers water alkalinity without removing other solids. Dealkalization is often used when both hardness and alkalinity need to be controlled.

Specific Ion Removal (e.g., Nitrates, Heavy Metals)

Ion exchange can also target specific contaminants like nitrates, arsenic, and heavy metals. This is critical for drinking water and wastewater treatment. Ion exchange effectively removes harmful metals or nutrients like nitrogen and phosphorus pollutants from wastewater. In drinking water, excessive fluoride or nitrate levels can be reduced to meet safety standards.

Applications Of Ion Exchange

It’s no surprise that after being used in various water treatments, ion exchange has a wide application. Here are its key applications in different sectors:

Ion Exchange in Drinking Water Treatment

Ion exchange is a trusted method for improving drinking water. The specialized resins in this procedure target these impurities. It’s commonly used to remove contaminants like boron, perchlorate, and uranium. Ion exchange also supports processes like dealkalization, deionization, and denitrification.

Ion Exchange in Wastewater Treatment

In wastewater treatment, ion exchange helps remove metal ions. It’s an efficient method for reducing heavy metal concentrations and protecting the environment. While effective, some challenges remain. Contaminants like arsenic, lithium, and fluoride are harder to remove due to resin limitations. Despite this, ion exchange remains a key tool for wastewater treatment.

Ion Exchange in Food and Beverage Processing

Food and beverage production requires selective and precise methods. Ion exchange is perfect as it reduces waste and turns batch processes into continuous, automated processes. With this, companies get improved quality of various products like fruit juice, wine, and dairy processing. It helps with demineralization and decolorization. Both of these processes convert minerals into valuable ingredients for baby food and pharmaceuticals.

Ion Exchange in Industrial Applications

In industrial settings, ion exchange is used as water pre-treatment. It softens the water for usage in boilers, heat exchangers, and other equipment. By using ion exchange methods, industrial appliances get longevity. It does so by reducing hard water’s scale buildup, which can damage machinery.

Advantages Of The Ion Exchange Process

Here are the main reasons why ion exchange is a preferred choice:

- Selective Ion Removal: Unlike other technologies, the ion exchange method excels in eliminating targeted contaminants.

- High Efficiency in Water Treatment: The resin beads in ion exchange processes are typically porous with a high surface area. They maximize the number of active sites available for ion exchange. This leads to the efficient removal of dissolved ions, improving water quality.

- Flexibility in Application: The process adapts easily to different water conditions and industries. From power plants to food production, it ensures reliable performance with the right resin selection.

Challenges And Limitations Of Ion Exchange

While effective, ion exchange comes with challenges that require consideration:

- Cost and Energy Consumption: Initial setup, regular maintenance, and the regeneration process can be costly.

- Resin Replacement and Regeneration Frequency: Resins degrade over time, requiring regular regeneration and eventual replacement. This increases operational costs.

- Environmental Considerations: Regeneration produces waste streams. If not managed properly, they can cause environmental harm.

Is Ion Exchange Right For Your Water Treatment Needs?

When it comes to the “hardness” of water, there’s no one-size-fits-all solution. Although Ion exchange is a widely used water treatment method, it may not work for you. So, consider these before installing an ion exchange water treatment technology:

Factors to Consider in Choosing Ion Exchange Systems

When evaluating ion exchange, consider these key factors:

- Type of Contaminants: Understand what types of minerals are causing the hardness of the water. At WaterMart, we provide free water tests. We also check if there are any lead or arsenic contaminants for an effective ion exchange system.

- Water Quality: Other key considerations include the desired purity level and the quality of the feed water. You also need to evaluate the resin type and capacity, operating pH, flow rate, regeneration needs, and the overall system size.

- Cost vs. Benefit: The cost is another important factor, as well as the particular application. Ion exchange systems are typically affordable for ongoing use but require periodic regeneration, which can add to operational costs.

When to Use Ion Exchange vs. Other Technologies

While ion exchange is effective for specific needs, other technologies might be more efficient for broader or different types of contamination.

- Water Softening: Households and industries that want to deal with hard water only will find ion exchange to be a reliable choice.

- Pollutant Removal: If your water has a wide range of impurities (like bacteria), reverse osmosis might be a better choice.

- Cost Considerations: If you need a high volume of pure water, reverse osmosis may be more effective. Ion exchange tends to be cheaper for treating lower concentrations of contaminants.

Improve Your Water Quality with WaterMart’s Water Softener Systems

Hardwater treatments are numerous, and picking the most “suitable” one for your needs is impossible without the right testing. At WaterMart Canada, we provide free water testing for anyone looking to improve water quality. Get a free water test quote today! Aside from tests, we also offer professional water treatment services for whole house water softeners as well as other filtration systems. Our team recommends and installs the right solution for your home, kitchen, restaurant, or business. Contact us today to discuss your options or schedule an installation.

Summary

If you’re facing water problems, installing ion exchange systems can make a huge difference. The ion exchange process is widely used for softening hard water, deionization, and removing contaminants like nitrates and heavy metals. It can even be used for drinking water. Just make sure to keep it maintained with regular resin regeneration.

FAQs

No, although both of them are water treatment methods, they are different. The main difference is that ion exchange targets certain ions. Whereas, reverse osmosis removes all particles larger than water molecules.

Yes, the ion exchange process removes lead from water. This process uses a resin (like strong acid cation SAC or weak acid cation WAC) with an ionic charge to capture lead ions.

The cost of an ion exchange water softener ranges from $500 to $6,000. It depends on factors such as size, brand, and installation complexity.

Ion exchange systems require regular maintenance, including resin replacement, which can be costly. Without proper care, resin performance degrades over time.

Yes, water treated through ion exchange is safe to drink. It is often used in bottled water production and household filtration systems.