Your cart is currently empty!

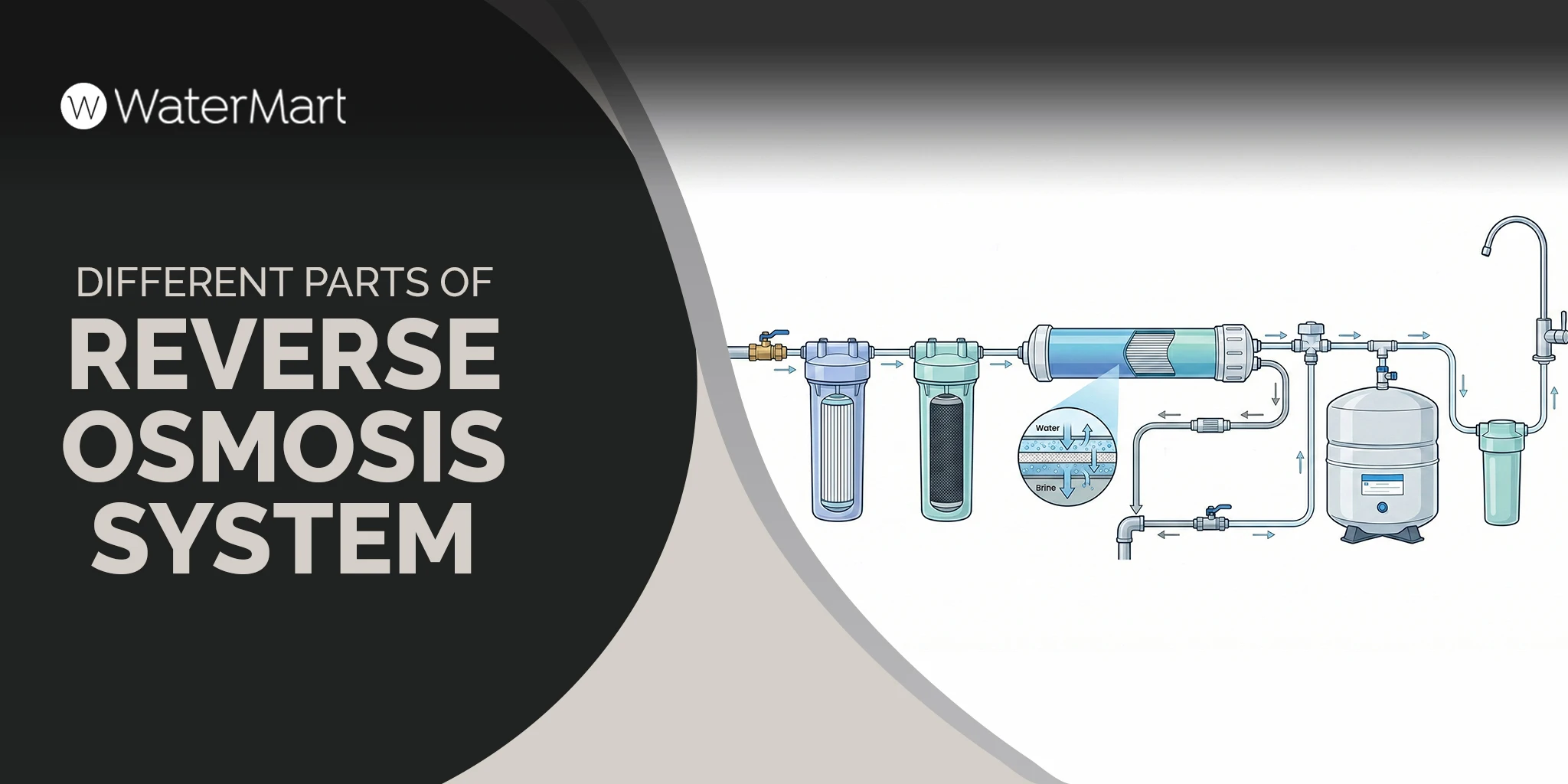

Key Parts of Reverse Osmosis System and Their Working Mechanism

Reverse osmosis, or RO, is a special water filtration system that pushes water through tiny filters to remove unwanted particles. It removes contaminants, metals, and chemicals, producing clean, healthy water for cooking and drinking.

To operate efficiently, an RO system relies on several critical parts. Proper assembly and installation ensure these parts work together to filter water and remove contaminants.

Understanding the components of a reverse osmosis system helps you grasp its operation and how each part affects water quality. So let’s explore all parts of reverse osmosis.

| Key TakeawaysAn RO system consists of multiple components that operate in sequence, and a failure in any single component affects the entire system’s performance.The RO membrane is the core of the system, but it depends on pre-filters to protect it from dirt and chlorine damage.Smart valves, such as the ASO valve and check valve, automate water production, prevent waste, and protect the membrane.Optional accessories like UV disinfection, TDS monitors, and remineralization filters can enhance water quality beyond the core system.Regular filter and membrane replacements are essential to avoid low flow, bad taste, and water waste. |

Parts of Reverse Osmosis System

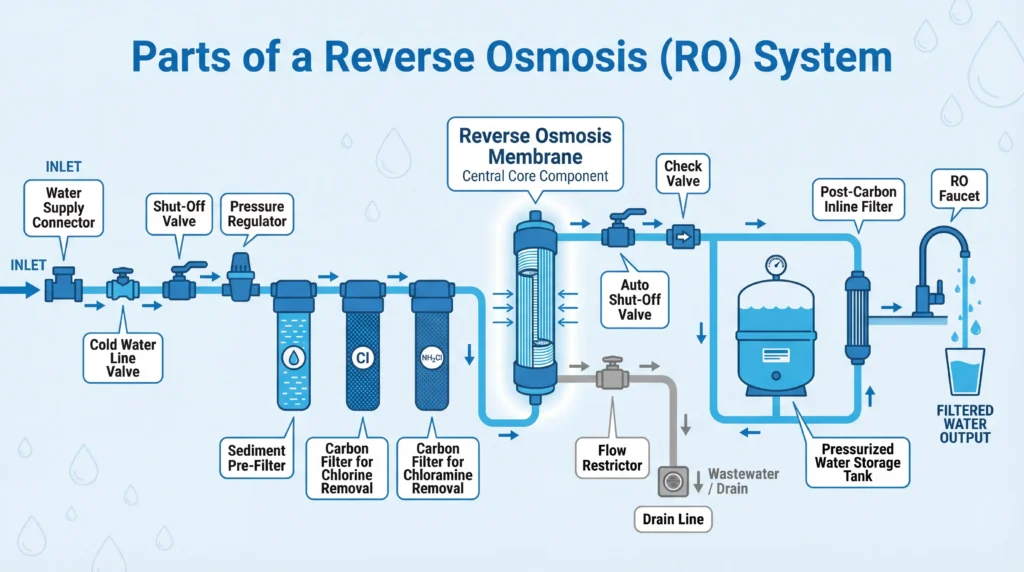

Reverse osmosis system parts work together to clean your water, while performing a dedicated job individually. From the first connection to your water pipe all the way to the faucet where clean water comes out. Given below is the breakdown of each important part and what it does to make your drinking water safe and pure.

Water Supply Connector

The water supply connector is the point of entry for your RO system. This small but important part connects your reverse osmosis system to your home’s main water line. It’s usually a brass or plastic fitting that attaches to the cold-water pipe under the sink. The water supply connector delivers water from your house to the RO system, enabling the cleaning process to begin.

Without this connector, your RO system wouldn’t get any water to filter. Most water supply connectors use a saddle valve or compression fitting to make a tight seal that won’t leak.

Cold Water Line Valve

The cold water line valve controls the flow of water going into your RO system. This valve sits between your main water pipe and the RO system, functioning as an opening that opens or closes on demand. When you turn this valve on, water flows into the system. When you turn it off, the water stops completely.

The cold-water line valve is very helpful when you need to replace filters or perform maintenance on your RO system. You can shut off just the RO system without turning off water to your whole house. This valve is usually a simple turn-style or ball valve that’s easy to use.

Shut-Off Valve

The shutoff valve is a safety device that stops water flow when your storage tank is full. This automatic valve senses the water pressure in your system. When the storage tank fills up completely, the pressure increases, and the shut-off valve closes to stop more water from entering. This saves water and prevents waste. Once you draw some water from the tank and the pressure drops, the shutoff valve opens automatically. This smart valve helps your RO system operate only when needed, improving efficiency and protecting other components from excessive pressure.

Pressure Regulator (Optional)

A pressure regulator controls how hard water pushes through your RO system. Home water pressure can be too high or too low, and an RO membrane works best at a specific pressure (usually 60-80 PSI, measured with a reverse osmosis pressure gauge).

If your water pressure is too high, it can damage the RO membrane and other parts. If it’s too low, the system won’t clean water properly. Not every home needs a pressure regulator; only those with very high water pressure do. A pressure regulator protects the RO system and helps it last longer.

Sediment Pre-Filter

The sediment pre-filter is the first cleaning stage in your RO system. This filter captures large particles such as dirt, sand, rust, and mud from your water. It usually has tiny pores (5 microns) that trap particles larger than a grain of salt. The sediment pre-filter protects the downstream filters, especially the expensive RO membrane, from clogging with sediment. Without this pre-filter, dirt would damage your RO membrane quickly. The sediment pre-filter needs to be replaced every 6-12 months, depending on how dirty your water is.

Carbon Filter For Chlorine Removal

The carbon filter removes the chlorine from the water and is the second stage in the whole filtration process. This filter uses activated carbon or GAC (special charcoal) to grab and remove chlorine from your water. Most cities add chlorine to tap water to kill germs, but this chlorine can damage TFC membranes over time. The carbon blocks or granules inside this filter are like tiny sponges that soak up chlorine and other chemicals.

This filter also removes bad tastes and smells from your water. It works together with the sediment filter to protect your RO membrane, which may become ineffective if exposed to 1000 ppm of free chlorine. Most people need to replace this carbon filter every 6-12 months to keep it working well.

Reverse Osmosis Membrane

The reverse osmosis membrane is the most important part of your RO system. This thin, specialized filter has tiny pores (0.0001 microns) so small that only water molecules can squeeze through. The RO membrane removes up to 99% of dissolved solids, heavy metals like lead and arsenic, bacteria, viruses, fluoride, nitrates, and hundreds of other contaminants.

It works by forcing water through the membrane under pressure while blocking all other components. The harmful particles or contaminants that don’t pass through go down the drain. A high-quality RO membrane can last 2-3 years before needing replacement, making it a great investment for clean water.

Auto Shut-Off Valve (ASO Valve)

The auto shut-off valve (ASO valve) is a smart component that saves water and protects your system. This valve automatically stops water from flowing into the RO membrane when your storage tank is full. It senses the pressure in both the feed water line and the storage tank.

When the tank pressure equals the feed water pressure, the ASO valve closes. This prevents your system from making more water than you need and stops wastewater from going down the drain constantly. The ASO valve also protects your RO membrane from running when it doesn’t need to, helping it last longer and reducing your water bill.

RO Check Valve

The RO check valve is a one-way valve that keeps water flowing in the right direction. After water passes through the RO membrane, the check valve makes sure it only goes forward to the storage tank and can’t flow backward. Without a check valve, water could reverse direction and push contaminants back into your clean water. This small valve also prevents pressure from the storage tank from pushing back against the RO membrane, which could damage it. The RO check valve contains a small spring and seal that opens when water flows forward and closes when pressure tries to push water backward.

Drain Line

The drain line carries away the dirty water that doesn’t make it through the RO membrane. When your RO system cleans water, it separates the pure water from concentrated wastewater full of contaminants. This wastewater, called reject water or brine, needs to go somewhere safe, usually down your sink drain.

Some water waste is normal in RO systems (typically 3-4 gallons of waste for every 1 gallon of clean water), but newer systems are more efficient and waste less water.

Flow Restrictor

The flow restrictor controls how fast wastewater leaves your RO system through the drain line. The flow restrictor creates back pressure that helps push water through the RO membrane efficiently.

If wastewater drained too fast, there wouldn’t be enough pressure to force water through the tiny pores in the membrane. Different RO systems need different flow restrictors based on the membrane size and your home’s water pressure. The right flow restrictor balances clean water production with wastewater to give you the best performance.

Post-Carbon Inline Filter

The post-carbon inline filter is the final refining stage before water reaches your faucet. Even though the RO membrane removes almost everything, this last RO carbon filter removes any remaining tastes or odors that might come from sitting in the storage tank. It also catches any tiny carbon particles that might come from other filters.

The post-carbon filter uses high-quality activated carbon to give your water a fresh, crisp taste. This filter is especially important if your water has been staying in the storage tank for a while. Replace this filter every 6-12 months to keep your water tasting its best.

Pressurized Water Storage Tank

The pressurized water storage tank holds your clean RO water until you’re ready to use it. Making RO water takes time (usually 2-3 hours to fill the tank), so the storage tank keeps several gallons ready whenever you need it. Inside the tank is a rubber bladder that separates water from compressed air.

The air pressure pushes water out quickly when you open your faucet. Most home RO systems have tanks that hold 2-4 gallons of purified water. The tank is usually fitted under your sink next to the RO system. Replace your storage tank every 5-7 years for optimized working.

RO Faucet

The RO faucet is the special tap where your clean reverse osmosis water comes out. This dedicated faucet installs on your countertop or sink (separate from your regular kitchen faucet) and connects only to your RO system. RO faucets come in different styles like chrome, brushed nickel, or oil-rubbed bronze to match your kitchen.

The faucet has a simple on-off handle or lever that controls water flow, an “air gap” to stop water from flowing back. Because RO water is so pure, it’s best to have a separate faucet just for drinking and cooking water. This keeps your filtered water separate from regular tap water you use for washing dishes. The RO faucet usually has a slower flow than regular faucets because it’s drawing from the storage tank.

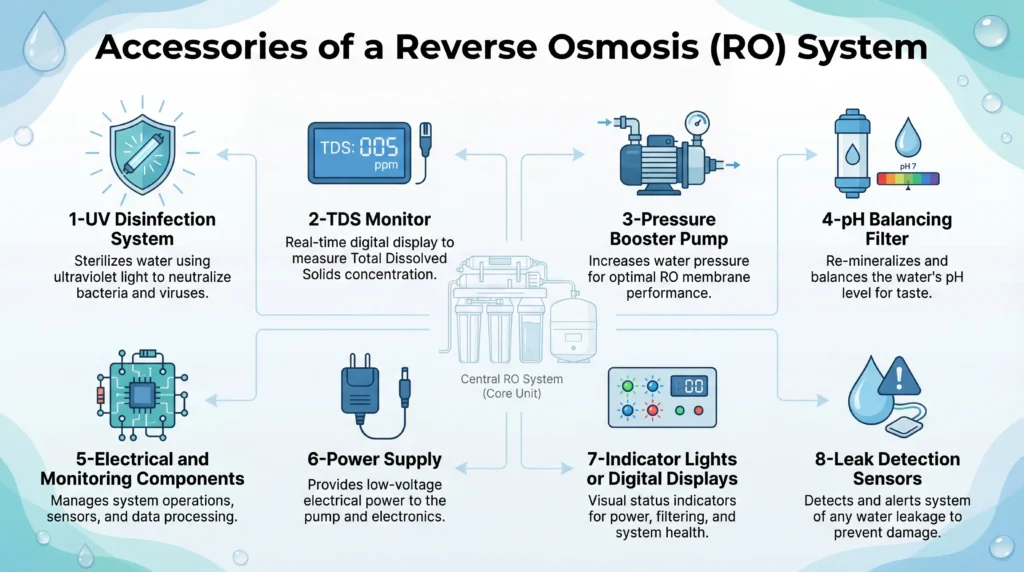

RO System Accessories

The above given RO water purifier parts are necessary for your RO system to work properly. However, there are some extra parts or reverse osmosis accessories you can add to make your system even better. These optional accessories can improve water quality, make your system easier to use, or help it last longer, but your RO system will still work fine without them.

UV Disinfection System

A UV disinfection system uses ultraviolet light to kill bacteria, viruses, and other microorganisms that might survive the RO membrane. The UV lamp is located in a chamber after the storage tank and destroys the DNA of harmful germs as water flows past it. This extra protection is especially useful if your water source is a well or if you want complete sterilization of your drinking water.

TDS Monitor

A TDS (Total Dissolved Solids) monitor measures the amount of minerals and contaminants in your water using electrical conductivity. The digital meter shows you a number in parts per million (PPM) that tells you how pure your water is, lower numbers mean cleaner water. This additional monitoring device helps you know when it’s time to change your RO membrane or filters by showing when water quality starts to drop.

Pressure Booster Pump

The booster works to increase RO pump pressure and pushes water through the RO membrane to make it faster and more efficient. You need this electric pump when your home water pressure is below 40 PSI or when you want to get more filtered water in less time. The pump also reduces wastewater by helping the membrane work at its best pressure level.

pH Balancing (Remineralization) Filter

A pH-balancing filter adds healthy minerals like calcium and magnesium back into your RO water to raise the pH and make it less acidic. RO water can be slightly acidic (pH 5-6) because it removes all minerals, and this filter restores a neutral pH (7-8) while improving taste. The remineralization filter uses natural minerals like calcite or corosex that slowly dissolve into your water as it passes through.

Electrical and Monitoring Components (If Equipped)

Modern RO systems with electric pumps and monitors need electrical components to power and control these features. These reverse osmosis water filter parts work together to automate your system, show performance data, and alert you to problems.

Power Supply

The power supply converts your home’s electrical current into the right voltage for your RO system’s pump and electronic parts. Most RO systems use a 24-volt or 36-volt transformer that plugs into a standard wall outlet. This low-voltage power is safe and provides steady electricity to run the booster pump and monitoring equipment.

Indicator Lights or Digital Displays

Indicator lights or digital displays show important information about your RO system’s status, like when filters need changing or if there’s a problem. Simple systems have LED lights that change color or blink, while advanced systems have LCD screens showing filter life percentage, TDS levels, and water production rate. These visual alerts help you maintain your system without guessing when maintenance is needed.

Leak Detection Sensors

Leak detection sensors are safety devices that sense water on the floor and automatically shut off your RO system to prevent flooding. The sensor is installed on the floor under your sink and triggers an alarm or cuts power to the system when it gets wet. This protection is valuable because it can save you from expensive water damage and alerts you immediately if a connection loosens or a part fails.

How These RO Water Purifier Components Work Together

Now that you know each part of an RO system, let’s see how they all work together like a team to give you clean water.

- Water starts moving in at the water supply connector and flows through the cold water line valve into your system.

- First, it passes through the sediment pre-filter that catches dirt and rust, then moves to the RO carbon filters(GAC and Catalytic) that remove chlorine and chloramine.

- After this cleaning, the water is ready for the RO membrane, which is the main filter that removes 99% of contaminants like heavy metals, bacteria, and chemicals.

- Once water squeezes through the tiny pores in the RO membrane, the check valve makes sure it only flows forward to the pressurized storage tank.

- The flow restrictor controls how fast dirty water leaves through the drain line, keeping the right pressure for the membrane to work properly.

- When you turn on your RO faucet, water flows from the storage tank through the post-carbon filter for final refinement, giving you fresh, clean water.

- Once the tank fills up, the auto shut-off valve cuts off the system, saving both water and electricity.

- All these parts work in perfect order, each doing its job to protect the next part and deliver the purest water possible.

If you’re looking for a reliable reverse osmosis system with all these quality components, WaterMart’s Reverse Osmosis Systems are designed to give you the cleanest drinking water for your family. Our RO systems include high-performance pre-filters, premium RO membranes, pressurized storage tanks, and all the essential parts you need for safe, great-tasting water. WaterMart uses top-quality materials and the latest technology to make your RO System work without any shutdowns. Contact us today and talk to our experts for further details.

Common Problems Linked to Specific RO Parts

Now the question arises, what if a component stops working or reaches its life cycle, or voids the warranty? See the impacts you may have, showing a clear sign that you need a component to be maintained or changed.

Low Water Flow

If you are getting low water flow at the receiving end of your RO system or in your output faucet, it might be due to the following reasons.

- Clogged sediment filter: it blocks incoming water when filled with dirt and debris.

- Blocked carbon filter: restricts flow if saturated.

- Fouled RO membrane: mineral buildup reduces water production.

- Low tank air pressure: The storage tank cannot push water properly.

- Kinked tubing or clogged flow restrictor: slows down water movement.

- Weak feed water pressure: RO systems need proper inlet pressure to work efficiently.

Bad Taste or Odor

An unpleasant taste or smell can completely ruin the quality of your drinking water. These symptoms often come from:

- Expired carbon filters (pre or post): no longer remove chlorine, chemicals, or odors effectively.

- Old RO membrane: allows dissolved solids to pass through.

- Dirty storage tank: Bacteria buildup can affect taste.

- Contaminated post-carbon (polishing) filter: fails to refine water before it reaches the faucet.

- Stagnant water: If the system hasn’t been used for a long time.

Constant Drain Flow

If your water is continuously running down the drain, look for the following reasons.

- Worn RO membrane: cannot build enough pressure to trigger shut-off.

- Incorrectly installed or clogged flow restrictor: disrupts pressure balance.

- Low tank pressure: prevents the system from reaching shut-off pressure.

- Leaking check valve: allows water to flow backward, keeping the system running.

- Faulty auto shut-off valve (ASO valve): fails to stop water production when the tank is full.

Slow Tank Refill

Sometimes the RO systems seem to be working fine. But you get a slow tank refill. If you face this problem, there could be the following reasons behind it.

- Clogged RO membrane: reduces filtration speed.

- Blocked pre-filters: limit incoming water supply.

- Low feed water pressure: RO membranes require adequate pressure (usually 40–60 psi).

- Cold water temperature: slows membrane production rate.

- Failing flow restrictor: affects system balance and refill time.

Role of Professional Installation in RO System Efficiency

What comes easily, goes easily. This is what happens with most DIYers while installing an RO system. Why? Because a layman is not trained to use the equipment and is unable to work properly while installing a RO Filtration system for maximum efficiency. An untrained person does not understand where the drain line goes, or how to mount a storage tank, or what’s the best way to adjust the flow restrictor for your home’s specific water pressure.

Hiring a professional reduces the guesswork while removing any mishaps or technical errors because whatever quality parts and systems you have, one wrong fit can turn your system into garbage. WaterMart offers expert professional installation services for your new RO system with certified professionals and years of experience. Our staff assesses your RO needs, better understands the capacity of your system, and installs the right system for you.

Wrapping Up on RO System Parts

When all of the parts of Reverse Osmosis system are aligned, properly installed, and well-maintained, they work together efficiently. In case one part stops working or becomes inefficient, the whole water filtration system can be affected. That’s why putting your RO system in a professional hand is highly recommended.

When you choose WaterMart’s installation service, we handle everything from connecting the water supply line to testing your system’s performance. We ensure you get clean, safe water from day one at minimal system cost. We also show you how to maintain your system, when to change filters, and answer all your questions so you feel confident using your new RO system for years to come.

Frequently Asked Questions

Carbon pre filter and sediment filters are the most frequently changed parts of an RO system. You need to change them every 6-12 months, depending upon their condition. The RO membrane is also a critical part, and it needs to be changed every 2-5 years based on its lifespan.

Carbon filters and RO membranes are kept separate because they serve different purposes in an RO system. Carbon filters absorb the chlorine, while the same chlorine can damage the membrane. So both of these components are separately fitted in RO systems for their best functionality.

Separate carbon filters are used for chlorine and chloramine because chloramine is difficult to remove from water, which cannot be done by pre-activated carbon filters. Chloramine is more stable and takes a longer time to get removed. So specialized catalytic carbon filters are used, which stay in contact with Chloramine for a long time. Whereas chlorine is removed by regular GAC (Granulated Activated Carbon) filters, which work efficiently on chlorine removal but have limited capacity for chloramine removal.

An RO faucet is different from the main kitchen faucet because it is not designed for high-volume water usage. It’s a small dedicated tap with a narrow tube(¼” usually) to handle low-pressure water dispensing, including an “air gap” to handle backflow contamination. You need special plumbing to install the tap that can help the faucet to dispense low-pressure water from the storage tank, without letting the drain water backflowing to the filtration system.

If a drain line flow restrictor doesn’t match your RO membrane size, it will mess up the pressure inside the system and stop it from working right. The flow restrictor needs to be 3 to 4 times bigger than what your membrane can produce each day, so there’s enough pressure to push water through the membrane while flushing dirty water down the drain.

No, all the RO system parts are not universal. Though some undersink parts are universal and are considered “standard” parts, many brands also sell proprietary filters, membranes, and fittings that are made to fit only their specific models.

If the Auto Shut-Off (ASO) valve in an RO system stops working and stays open, the system will not stop making water. Water will keep flowing down the drain even when the tank is full. This wastes water, can raise your water bill, and may damage the filters and membrane over time.